- 09/12/2025

- Companies: strategies and future

Rehau Interior Solutions, the Rehau Group division specialized in supplying components for the furniture industry, has a rich portfolio of products designed to offer furniture industry professionals the greatest freedom in design choices, configuration and material processing, guaranteeing high quality standards and attention to sustainability.

We discuss this with Andrea Bucciarelli, Director Furniture Systems of Rehau S.p.a., who outlines both the company's product innovations and the real commitment of the Rehau Furniture Solutions division to measurable sustainability.

Materials — increasingly sustainable, intelligent and high-performing — have become a central theme in design. How do your innovation strategies express themselves?

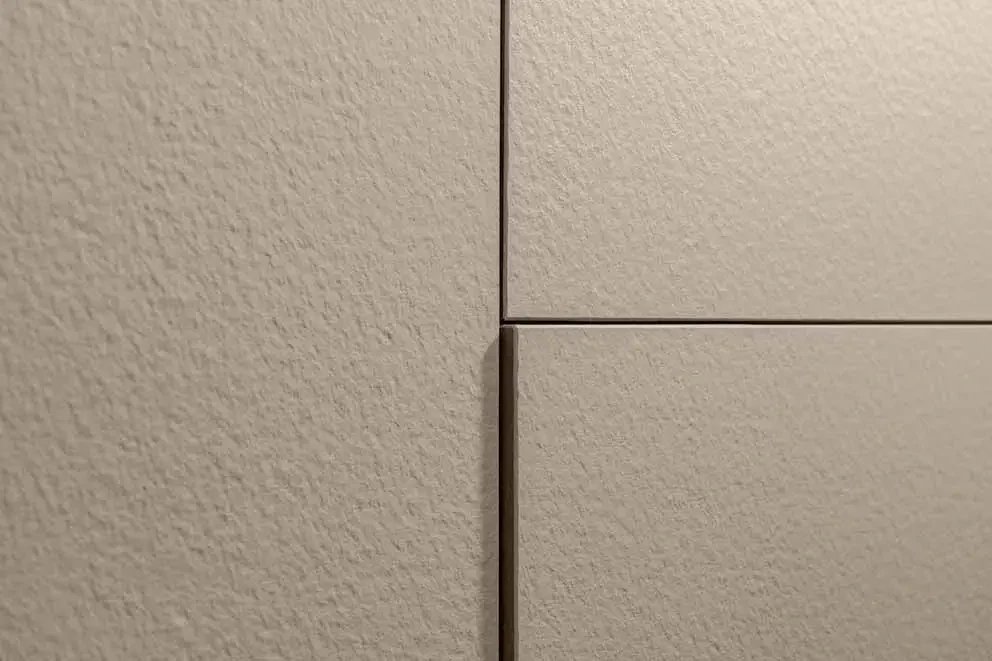

Innovation, for Rehau, arises from continuous dialogue between the different sectors in which we operate. Our long-standing experience in polymer extrusion, gained in areas such as automotive, plumbing and heating, window profiles and industry, allows us to transfer advanced technologies into the furniture world, raising the quality of products available on the market. This interdisciplinary approach translates into edges, surfaces and roller shutters that combine technical performance, long-term stability and maximum attention to aesthetics and sustainability. This is the case, for example, with the Rauvisio crystal acrylic laminate surfaces, our “smart glass” that meets the growing demand for materials with a sophisticated appearance but superior mechanical characteristics compared to traditional glass. Likewise, the expansion of our range of surfaces with new textures, such as the stone-effect texture of Rauvisio cube Desert Stone, presented at SICAM 2025, demonstrates our ability to anticipate stylistic evolutions with premium-quality proposals.

Rauvisio cube Desert Stone Nutmeg Brown surface with the new stone-effect texture

Responsible innovation increasingly manifests itself through the use of recycled and recyclable materials or through green technologies and production processes that reduce environmental impact. How does Rehau respond to this now-priority topic in business strategies?

For Rehau Interior Solutions, as for the entire Group, sustainability is part of a strategy rooted for years, not a recent market adjustment. We were among the first manufacturers to completely eliminate PVC from edges, decisively focusing on more eco-friendly polymers such as polypropylene, now recognized and requested even by major international players. There was also the integration of the line of edges made with a 50% recycled material content, Raukantex eco, and the roller shutters made 100% from recycled PP, Rauvolet eco.

Rauvolet eco roller shutter made 100% from recycled PP

An additional step forward is represented by a leadership we consider strategic for the sector: Rehau Interior Solutions is the first components supplier to make official Product Environmental Declarations (EPD) available for the main solutions in its range, namely Raukantex edges, Rauvisio surfaces and Rauvolet roller shutters. A commitment that materializes in a conscious choice for designers, based on total transparency of our products' environmental impact across the entire life cycle, with data certified by the independent body Bauen und Umwelt e. V. (IBU). We are convinced that tools like EPDs represent the future of industrial sustainability, because they allow the market to distinguish between real commitment and superficial communication.

How much can the new European Ecodesign regulatory framework influence sustainable design processes?

The new European regulations accelerate a path already underway: sustainability will no longer be a declared value but measured. In this sense, being among the first companies in the Furniture Industry to provide certified EPDs allows us to anticipate Ecodesign requests, already offering today a level of transparency above current requirements. The regulation will also help create more uniformity among operators, promoting recyclable materials, more efficient processes and a precise assessment of environmental impact throughout the supply chain. Companies that, like us, have invested in real sustainability will benefit from this new scenario as they will be able to leverage their know-how and offer the market solutions already fully compliant.

In an increasingly competitive market, customization is a strategic topic. Therefore, a more proactive collaboration between company and clientele makes it possible to respond precisely to their needs; in particular in fast-growing sectors such as contract, hospitality or the marine sector. How does your company address this topic?

Customization is one of the pillars of our offering. We do not impose an aesthetic; we work alongside partner customers to create solutions that precisely meet their needs, both technically and aesthetically. A concrete example of this are the new premium edges Raukantex canvas which, thanks to a new digital technology similar to 3D printing, allow perfect synchronization between print and embossing. This technology is highly advanced and fully in line with the needs of those operating in high-end contract, where detail customization is an identity element of the project, but also in hotellerie and the nautical sector. In addition to these innovations already available, we will continue to expand our range of surfaces with finishes that respond to an increasingly segmented market, which demands aesthetic coherence and consistent quality even on large productions.

New premium Raukantex canvas edges

en

en  Italian

Italian French

French German

German Spanish

Spanish Portuguese

Portuguese