Materially, a leading Italian company in the research of innovative and sustainable materials for the manufacturing industry, organized an interesting webinar on July 3 entitled “Soft & Sound,” dedicated to sustainable and innovative padding materials for a conscious market.

The meeting was attended by the managers of three companies, Orsa foam, Mariantonia Urru, and EcoLattice, who presented three innovative materials, each with a distinct sustainable approach to comfort and performance, recently introduced to the market.

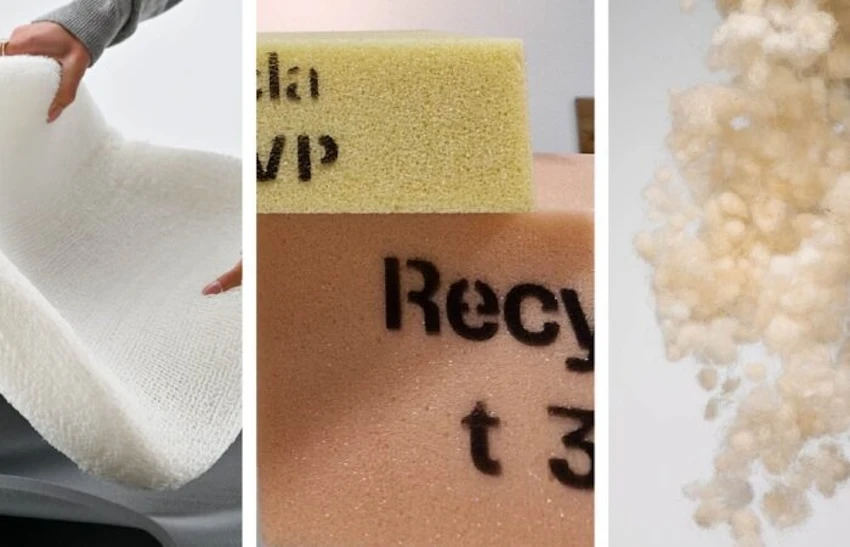

Recycla® by ORSA foam: the future of polyurethane

Orsa foam, one of the most important companies in the flexible polyurethane foam sector, has always been active in the field of sustainability and environmental protection, both through the development of sustainable products and through the adoption of targeted production processes and internal policies.

Davide Galli, from the Orsa foam marketing team, illustrated the company's journey towards sustainability, which began in 2006 with Gaia®, a polyurethane composed of water and raw materials derived from renewable sources that uses soy-based raw materials. This journey continued in 2021 with RisOrsa®, a range of flexible polyurethane foams with reduced environmental impact, made with high percentages of bio-based polyols derived from renewable sources. Orsa Foam's environmental commitment is also pursued through the production of the Rebound H and Rebound R agglomerate ranges, which have obtained “Plastica Seconda Vita” certification.

Orsa foam is now taking a further step towards sustainability with Recycla®, a new range of flexible polyurethane foams based on the recovery and transformation of waste raw materials into high-quality, high-performance polyurethanes. Andrea Cirani, Director of Research and Development at Orsa foam, illustrated its characteristics and explained that, thanks to an advanced chemical recycling process, it is possible to transform end-of-life mattresses into new resources, reducing dependence on fossil raw materials and contributing to the circular economy.

The Recycla® Polyether range is made from recycled polyurethane foam from discarded mattresses, which is returned to its polyol state to create new high-quality foams. The polyol used for Recycla® Polyester, on the other hand, comes from recycled PET plastic, allowing post-consumer plastic to be reused and limiting the dispersion of this waste in the environment.

The company's goal is to include recycled polyols in all formulations that allow it, without altering the physical and mechanical characteristics of the products.

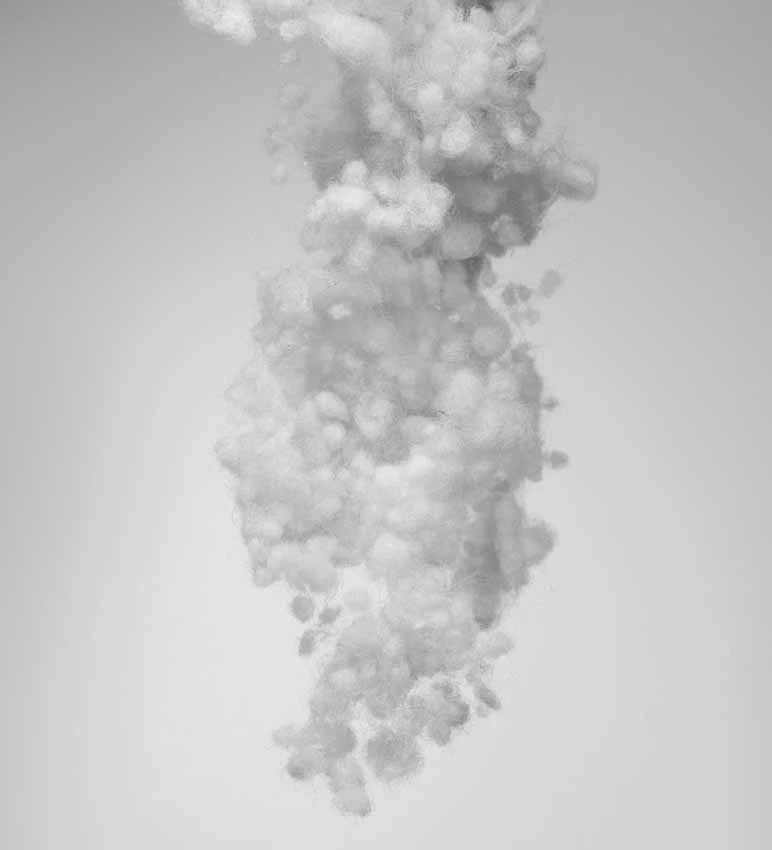

Mariantonia Urru: reinventing wool processing waste

An icon of Italian excellence, Mariantonia Urru combines traditional craftsmanship and contemporary design in a unique atelier, where each garment is spun, woven, and finished by hand in-house. The brand's philosophy is based on eco-sustainable design processes, the use of local materials, and manual labor for low-impact, low-waste production. Added to this is now research into wool processing waste and its unexplored potential as a naturally renewable material.

Dea Selmani, head of the company's international team, explained how, thanks to its intrinsic hygroscopic, insulating, sound-absorbing, and fire-retardant properties, wool offers new opportunities for circular innovation in all sectors, from furniture to mobility, fashion, and beyond. Wool thus becomes the basis for a new line of products adaptable to countless sectors: pressed panels made from 100% wool yarn production waste, semi-rigid fiber panels made from a dense, two-component wool blend, soft fiber padding composed of wool and hemp in various proportions, and wool balls for padding. Examples of applications for these new products were recently seen at the Salone del Mobile in the Sheep chair and the Soft Wool table at the Mariantonia Urru stand (pictured), as well as at the Cassina showroom in a project by Patrizia Urquiola and in the solutions proposed by Bolzan Letti.

EcoTPU by EcoLattice: the potential of 3D printing

EcoLattice is a British company that offers solutions using sustainable materials, integrating recycled thermoplastic elastomers (TPE) and advanced 3D printing.

The innovative material presented at the Materially webinar is EcoTPU, a recycled thermoplastic elastomer used by the company to create lightweight and comfortable lattice structures, exploiting generative design and 3D printing technologies. Thanks to these technologies, a range of materials can be developed in an economical, rapid, and above all sustainable way.

As Harinad P. Manoj, head of EcoLattice, explained, this material has various applications ranging from furniture to wellness, healthcare, and automotive. It is lightweight, easy to clean, extremely hygienic, durable, fireproof, customizable, and “zero waste,” meaning it has minimal environmental impact. EcoLattice's 3D-printed foams therefore offer new possibilities for comfort and breathability, making car and office seats, as well as those in the healthcare sector, more ergonomic.

en

en  Italian

Italian French

French German

German Spanish

Spanish Portuguese

Portuguese