- 06/02/2026

- Companies: strategies and future

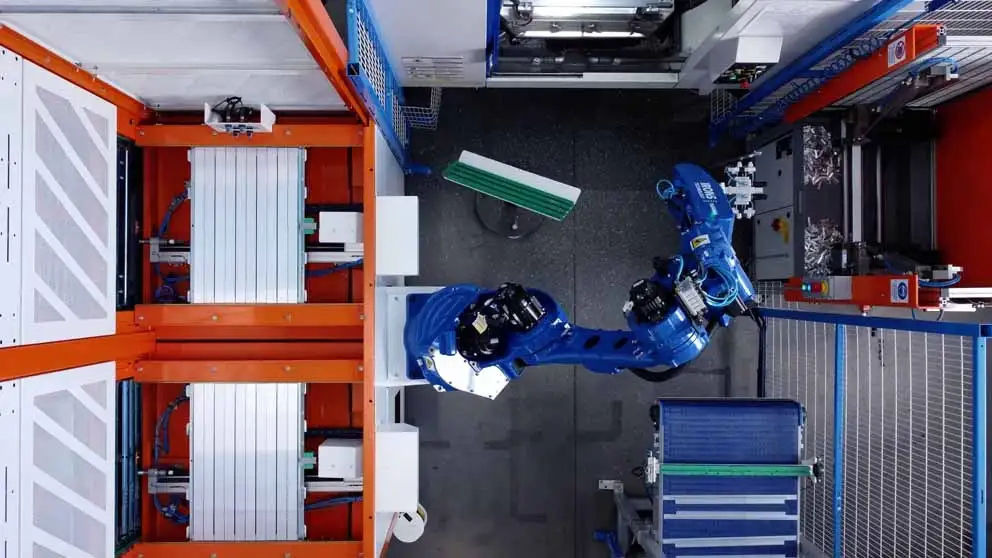

Efficient design and cutting-edge production, which rely on automation and digitalization to ensure process efficiency and quality, characterize Eureka, a company that since 1987 has manufactured furniture handles and accessories for the furniture industry.

Innovation, customization and industrial flexibility strategies: we discuss them with Simone Cimitan, Sales Director of Eureka.

Materials, increasingly sustainable, intelligent and high-performing, have become a central theme in design. How do your innovation strategies manifest?

For us innovation goes “hand in hand” with the customer: we listen to technical and commercial needs, identify trends and design languages and turn these directions into concrete and industrializable solutions. In this process the technical office is central: it is always at the forefront in designing, prototyping and validating new proposals, minimizing the gap between idea and finished product.

Today the possibility to design digitally and to have 3D-printed samples quickly is a decisive accelerator: it allows us to quickly pinpoint the “right” article for the customer, avoiding unnecessary redesigns and reducing waste and suboptimal productions. It’s an approach that makes development leaner and, at the same time, more sustainable and efficient.

Our design is increasingly “sensitive” to efficiency: we work to reduce weights and involved processes, simplifying where possible while maintaining performance, longevity and perceived quality. The goal is to make the product more functional and industrially competitive, without giving up the design freedom and aesthetic value that the sector demands today.

Hide wall unit, designed by Andrea Federici

At Sicam 2025 there was a noticeable return of handles perfectly integrable with the furniture and fully customizable. Which products best meet these characteristics?

The handle remains a key element of technical development and design within the kitchen: it is a small component, but highly identifying. The market requires a lot of variability and every customer wants to differentiate; this leads us to constantly update the finishes catalog, both anodized and painted, and to work on design to meet both classic and contemporary needs, with increasing attention to aesthetic integration with the furniture.

Eureka knobs: design and perfect aesthetic integration with the furniture

Responsible innovation is increasingly expressed through the use of recycled and recyclable materials or through green technologies and production processes that reduce environmental impact. How does your company respond to this now-priority topic in corporate strategies?

Our innovation strategies are a natural evolution of our approach to sustainability, which we already highlighted last year. Today, innovation at Eureka focuses mainly on low-impact materials, prioritizing raw materials from circular supply chains with recognized certifications, and on Intelligent Technologies for Durability. We invest in researching finishes and treatments that not only enhance aesthetic performance but also increase component longevity and resistance, thereby reducing environmental impact in the long term.

How much can the new European Ecodesign regulatory framework influence sustainable design processes?

The European regulatory framework is a powerful accelerator for our future strategy. Rather than seeing it as a constraint, we consider it a guide to ensure that our commitment is aligned with the highest standards.

In an increasingly competitive market, customization is a strategic issue. Therefore a more proactive collaboration between company and customers allows responding promptly to their needs. How does your company address this topic?

Customization is one of our greatest competitive advantages, as demonstrated by our approach that allows us to go beyond the simple catalog. We have optimized our production processes to efficiently manage small and highly variable production batches without compromising delivery times. Our flexibility allows us to 'tailor' the product, guaranteeing the customer a quality component rather than a compromise.

Composia Sideboard, modular aluminum frame with an essential and intelligent design

Facing an ever-evolving scenario, how is your company preparing to respond? Will you target other markets, and which ones?

We are preparing with a very pragmatic approach: more market insight, greater industrial flexibility and a commercial portfolio less dependent on a single segment. We will continue to invest in the core business related to furniture, but in parallel we are working on a diversification into adjacent markets where aluminum and high-quality finishes are required for both aesthetic and functional reasons.

Looking ahead, what do you expect 2026 to be like and what strategies should companies in the sector adopt to manage the economic situation in a context of global instability?

We expect another year marked by volatility: fluctuations in energy and raw material costs, pressure on margins, uneven demand and more aggressive price competition. In such an unstable context, companies in the sector will need to plan for scenarios, protect margins with a more dynamic product and pricing mix, increase efficiency and development speed while reducing waste, diversify markets and channels (strengthening exports) and make the supply chain more robust, thus combining operational reactivity with value positioning without losing quality, service and innovation.

en

en  Italian

Italian French

French German

German Spanish

Spanish Portuguese

Portuguese